1Piston PTFE Banding Machine

Operation – Insertion of PTFE(Polytetrafluoroethylene) bands on pistons.

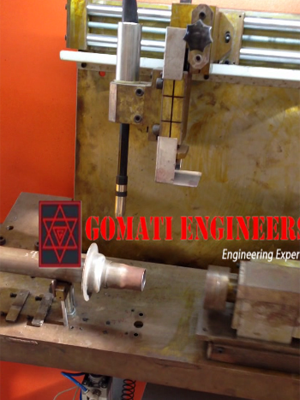

Read More2Piston Grooving Machine

Operation – To make groove (OD profile to fix up PTFE band on piston)

Read More3Noise Testing Machine for Two Wheeler

Operation – To detect noise level at different liner speeds of rod.

Read MoreOperation – To detect noise level at different liner speeds of rod.

Read More7Piston Coining Machine

Operation – To prepare flat land seat on base valve for valve discand to maintain Land relationship on piston.

Read More9Base Cap Bracket Welding Machine

Operation – MIG welding of tube to base cap, bracket/ spring seat

Read More10Spring Seat Welding Machine

Operation – MIG welding of tube to base cap, bracket/ spring seat

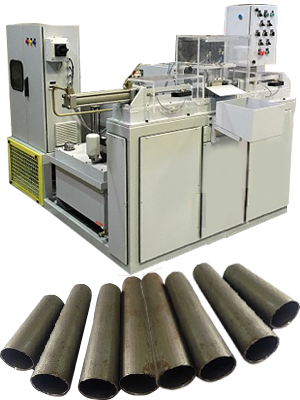

Read More11End Sealing/Roll Over System Machine

Operation – To seal outer tube ends, continuous bending.

Read More13Tube End Swedging/Flaring Machine

Operation-To decrease or increase tube diameter at ends up to specified length.

Read More14Shocker Final Assembly Machine

Operation – To fix eyelet on rod side after placing and compressing spring.

Read More15Bump Retainer Load Test Machine

Operation – To check bump retainer position shifting by applying load on retainer.

Read More16Inner Tube Ball Pass Machine

Operation – To check bump retainer position shifting by applying load on retainer.

Read More17Outer Tube Marking Machine

Operation – To mark manufacturers logo, model no. and other details.

Read More